Polished Cement Tile Benefits

Posted by William Buyok on

Polished, unpolished or raw are all terms that are used to describe the finish of cement tile. Polishing and the finish of cement tile is widely misunderstood and adds confusion when you compare prices, slip resistance, ease of installation, and the desired look. It's important to know what polishing is, how it changes the tile, and why it can be beneficial to specify polished tiles, when available.

What is Cement Tile Polishing?

When cement tiles ship from the factory, you may have the option to specify a "polished" or "unpolished" finish. Unpolished tiles may also be noted as having a "raw" finish and will usually appear slightly "chalky" when pulled from the box. Most factories only manufacture unpolished or raw cement tiles. However, one of our manufacturers provides the option to receive factory-polished tiles.

Watch Cuban Heritage cement tiles as they are polished at the factory in this short video, Cement Tile - The Polishing Process.

Frequent Question and Answers about Polished Cement Tile

-

What is polishing?

Polishing is a mechanical process that uses a high-speed rotary buffer, mild abrasives and water to "polish" each cement tile. The process simulates the "patina" a cement tile might develop after years of being cleaned with wax and water. -

Are polished tile really shiny and slippery?

No. Polished tiles have a moderate, flat satin look and are not as rough to the touch. Polished cement tiles are acceptable for floor applications. It should be noted that while the coefficient of friction of a polished tile is within the acceptable range of slip resistance, it is different than that of the unpolished tile. -

Will polished tiles have a longer life?

No. Polishing the tiles does not increase the life of the tiles. -

Do polished tiles require more maintenance since high-tread areas will wear down the "polish" and produce "walking lanes" over time?

No. Factory polishing is not like wax on a hardwood floor. The factory polishing process does not create a "layer of polish" on top of the tiles. If not properly maintained, tiles may develop shiny "walking lanes" in high traffic areas. To avoid this problem make sure the floor is evenly maintained and cleaned. -

What is the advantage to polishing tiles?

Once installed, the tiles immediately create a "lived in" feel with a softer satin sheen. This same effect will occur with normal care over time.

Benefits of Polished Cement Tile

Now that you understand what polishing is and how it is done, let's discuss the benefits and when you might consider using polished cement tile, if available. As I mentioned above, most factories only manufacture unpolished or raw cement tiles. Polished tiles are slightly more expensive and you should remember that when comparing costs.

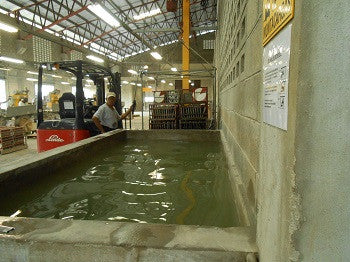

Cement tiles are placed on metal racks to dry after they are made

Racked cement tiles are lowered into a water bath to cure for 24 hours.

Color bleed can occur when the tiles are removed from the water bath

Finally, polished tile are usually easier to install because grout doesn't stick to the slightly smoother surface. In general, a grout release is not required for polished tiles. Whereas, on raw cement tile, I think it is a good precaution.

The only time I don't recommend polished tile is for exterior patio applications. Quite simply, the polishing benefit is lost quickly over time to the elements of wind, wear and weather. Additionally, if a project is time sensitive, you may want to forgo polishing the tile since the tiles need to fully cure before they can be polished and additional time is required for the polishing step.

Cement Tiles that are Available with a Polished Finish

Helpful Guides About Cement Tile

Share this post

- Tags: Cement Tile, Polished Cement Tile