Cement Tile: 7 Things You Need to Know Before You Buy

Cement tile is different in many respects than its more ubiquitous cousin, ceramic tile. It's these differences that often surprise folks and let's face it, nobody needs a surprise like that. To prevent that kind of a surprise, here's what you need to know before buying cement tile.

1. Use a very narrow grout line when installing cement tiles. Place cement tiles as close together as possible to create a very thin grout line. Minimizing the grout line will make the design look seamless and your space look larger. We recommend a 1/16" grout joint. Non-sanded (or unsanded) grout is required for grout joints less than 1/8"wide.

.

2. Pick the right grout color. You may use colored or white grout. If you decide to use colored grout, then we recommend it be a color that is the same or lighter than the lightest color used in the pattern. You can't use black grout with white or black and white pattern tiles because the dark grout will permanently stain the white parts of the tile.

3. Expect to spend about $1,000-$1,500 for tiles and freight on small projects. This price range is based on tiling 40-50 sq. ft. and assumes you will be using 8"x8" patterned tiles tiles for a backsplash, fireplace or small powder room. The cost, which will vary, will ultimately depend on the size, pattern, color and finish of the tile.

4. Expect the cost of freight to be about 30% to 45% of the total order. The cost of freight for even small cement tile orders can exceed the cost of the material. This is common for small projects when using cement tiles for a fireplace, backsplash or a small bathroom. The cost of freight increases more so when you aren't near a large city or major shipping lane. Cement tiles are heavy and usually need to be shipped as "freight" via common carrier.

Cement tiles are used on the wall and floor in a powder room

5. Add 20% overage/waste to the required tile quantity. We recommend ordering an additional 10%-15% of tile to cover overage/waste. Overage or waste accounts for uncertainty in dimensions, tile variations, damage during installation, and damage that may occur during shipping.

6. Purchase polished tile, if available. Most factories only manufacture unpolished or raw cement tiles. Currently, only one manufacturer provides the option to receive factory-polished tiles. Polished tiles have a satin sheen that simulates the finish all cement floor tiles achieve over time with care and use. The sheen develops from the abrasive forces acting on the tile from use. Raw tiles can be polished with a floor buffer and green pad after installation. But, the sheen won't develop immediately. Buffing will remove any surface color bleed on cement tile; but, you won't be able to us a floor buffer on a vertical backsplash installation. More information about cement tile polishing is available in our blog post, Polished Cement Tile Benefits Also, polished tiles are usually easier to install because grout and mortar doesn't stick to their slightly smoother surface.

7. Seal the tile with a penetrating sealer. Cement tile must be sealed with a high quality penetrating sealer. Like natural stones, cement tiles are porous in nature and a penetrating sealer provides a barrier by coating the cement particles in the tile, making it less likely they will retain stains or water. Our blog post, Sealing Cement Tile, will familiarize you with the different types of sealers and how they work. While water-based sealers are better for the environment and don't produce the strong fumes when applied; I prefer solvent-based sealers and feel they provide the best protection.

Additionally, A good solvent-based penetrating sealer is Fila Fob. We have recommended Fila products for years, but often, they have been difficult to obtain outside large metropolitan areas. Thankfully, you can purchase Fila Fob and all Fila products in small or large quantities online at SealersRus.com. The owner of the company, Ali Madani, is extremely knowledgeable about Fila sealers and their application for both tile and stone.

Always get a sample of the sealer and test it on a spare tile or in an inconspicuous place to make sure the desired effect is achieved. On vertical applications, the sealer needs to be applied lightly, often with a sponge, to avoid streaking.

Color bleed is common on high contrast tiles, such as patterns that use black and white.

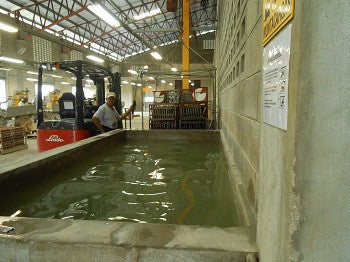

Color bleed occurs when cement tiles, placed in racks, are removed from a water bath that is necessary to strengthen the tiles. The water picks up trace amounts of pigment and drains down the tile. The dark pigments wash over the lighter areas of the tile, leaving a faint discoloration.

Cement tiles dry on metal racks

Cement tiles dry on metal racks

.

Racked cement tiles cure when lowered into a water bath.

This is normal and part of the manufacturing process. However, it may not be desirable for backsplash tiles that are in the limelight, so please keep that in mind.

Case Studies

Example #1

Here's a recent order that supports the points we made about what to expect for total cost and freight. This order was for a project we shipped to Brooklyn, NY. The customer needed 40 sq. ft,. or 92 pieces of 8"x8" tile. With waste or overage at 20%, we ordered 110 tiles.

| Item | Quantity | Price Each | Total |

|---|---|---|---|

| Trad. Neiba Cement Tile 8"x8" Polished | 110 | $7.46 | $820.60 |

| Pallet Fee | 1 | $20.00 | $20.00 |

| LTL Freight (450# FCA 33178) Residential. Lift Gate Required. |

1 | $340.00 | $340.00 |

| Total | $1,180.60 | ||

The freight cost is about 33% of the total order cost. The tile costs are in the range we predicted. In this case, there was no damage to the tiles during freight; but, the customer was glad they purchased extra for testing their sealer and the cuts that were required.

Example #2

In this example, the order was for a project we shipped to San Francisco, CA. The customer needed 52 sq. ft., or 120 pieces of 8"x8" tiles. With waste or overage at 10%, we needed at least 132 tiles and the customer decided to get a few extra.

| Item | Quantity | Price Each | Total |

|---|---|---|---|

| Trad. Bayahibe Cement Tile 8"x8" Polished | 135 | $7.46 | $1,007.10 |

| Pallet Fee | 1 | $20.00 | $20.00 |

| LTL Freight (500# FCA 33178) Residential. Lift Gate Required. | 1 | $480.00 | $480.00 |

| Total | $1,507.10 | ||

As you can see, the freight cost is about 35% of the total order cost. The tile costs are in the range we predicted. In this case, there was damage to one box caused by the carrier hitting the pallet with a fork-lift. Fortunately, the customer had purchased a few extra tiles and was able to complete the project without delay.

We're Here to Help

If you need further assistance or have any questions about cement tile, then please feel free to call our offices at 888.739.4972, or email us at info@AventeTile.com.

Download Cement Tile: 7 Things You Need to Know Before You Buy.